OUR Facilities

SeaDragon offers its customers a unique proposition: agile, state-of-the-art Omega-3 oil refining facilities operated by our team with world-class technical expertise and solid global supply relationships. All backed by a process that is fully certified and independently audited so you can be assured of the quality and reliability of SeaDragon products in your supply chain.

THE SEADRAGON QUALITY SYSTEM

Our modern Omega-3 refinery, commissioned in 2016, has the capacity to produce up to 5,000 tonnes of premium quality, fully-refined Omega-3 oils per year.

Omega-3 Refinery

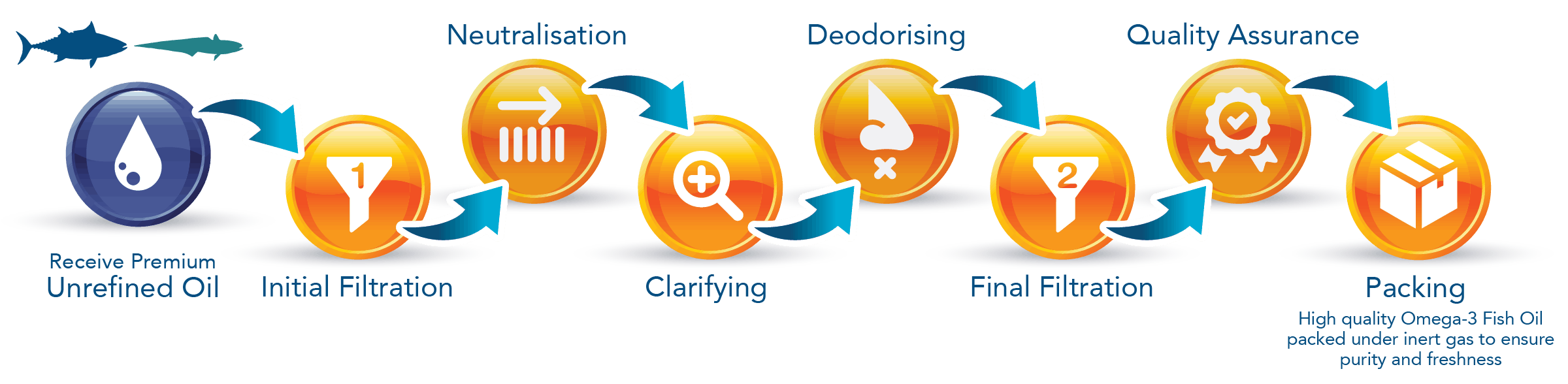

SeaDragon’s new Omega-3 oil refinery was fully commissioned in 2016. The state-of-the-art facility, built with industry-leading refining technology, has the capacity to produce 5,000 tonnes of Omega-3 oil each year. It is a highly flexible plant offering customers continuous process refining and quick-turnaround batch processing runs. These capabilities set SeaDragon apart from mass-scale refiners’ processing capabilities and allow the flexibilty to meet the demands of bioactive ingredients brokers and fortified food manufacturers.

The plant has the certifications necessary to export products to key target markets including Australia, many Asian markets including China and Japan, the European Union, the US and Canada as well as independently-audited chain of custody quarantine certifications.

Boutique Refinery

SeaDragon is fortunate to have a boutique refinery to produce smaller volumes of specialised Omega-3 products tailored for the most exacting standards.

Refinery Certifications

Our facilities operated to international best practice standards and independently audited. We are FSSC22000 certified, and Ministry for Primary Industries (MPI) certified as an approved Transitional Facility with Risk Management Programmes. Sustainability and market access certifications are maintained through Friend of the Sea (FoS), Marine Stewardship Council (MSC), halal and kosher certifications.